Insulated Sliding Doors

Insulated sliding doors –

customise them your way.

Insulated sliding doors are durable, customisable, can be used across multiple

applications and even automated – your doors, your way.

AceDoors Insulated Sliding Doors

Following years of experience within the coolroom market, AceDoors are proud of our superior product range.

Our Insulated Sliding Doors are visually attractive with the ability to suit the needs of each individual business, our Insulated Sliders are highly customisable and can be installed as chiller, freezer, or ambient process doors.

Adapted to several different environments, our Insulated Sliders have been installed in applications such as laboratories, food manufacturing process rooms, chicken sheds, hospitals, and clean rooms.

Enquire about our Insulated Sliding Doors.

Interested about using our Insulated Sliding Doors for your next project? Talk to one of our Specialists today.

Tech Specs – Process Sliding Doors

Door shall be AceDoors Sliding Doors as supplied by Ace Door Systems Ltd.

A. 50mm, 75mm or 1500mm think EPS insulated panel door leafs available.

B. Standard with 0.59BMT G2 Coloursteel (Titania) panel finish.

C. Door leaf fitted with silicone gaskets that meet food industry hygiene and safety requirements.

A. Doors complete with aluminum frame.

B. Frame includes thermal breaker strip.

C. Standard 3-sided frame with door bottom wiper gasket.

D. Back flashing included.

E. Low temperature doors standard with heated frame.

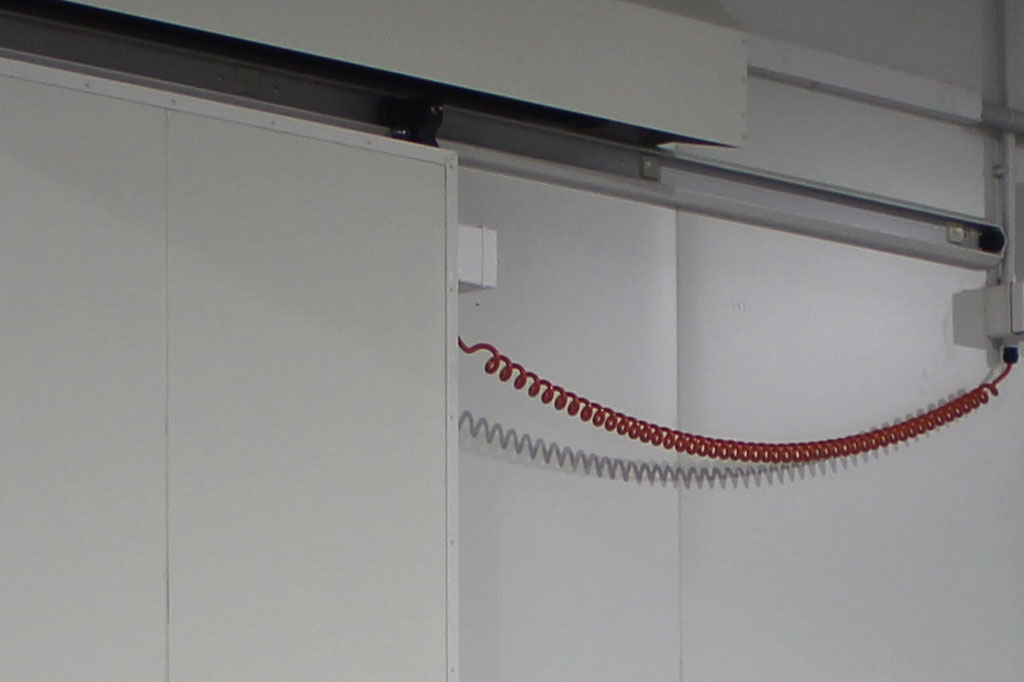

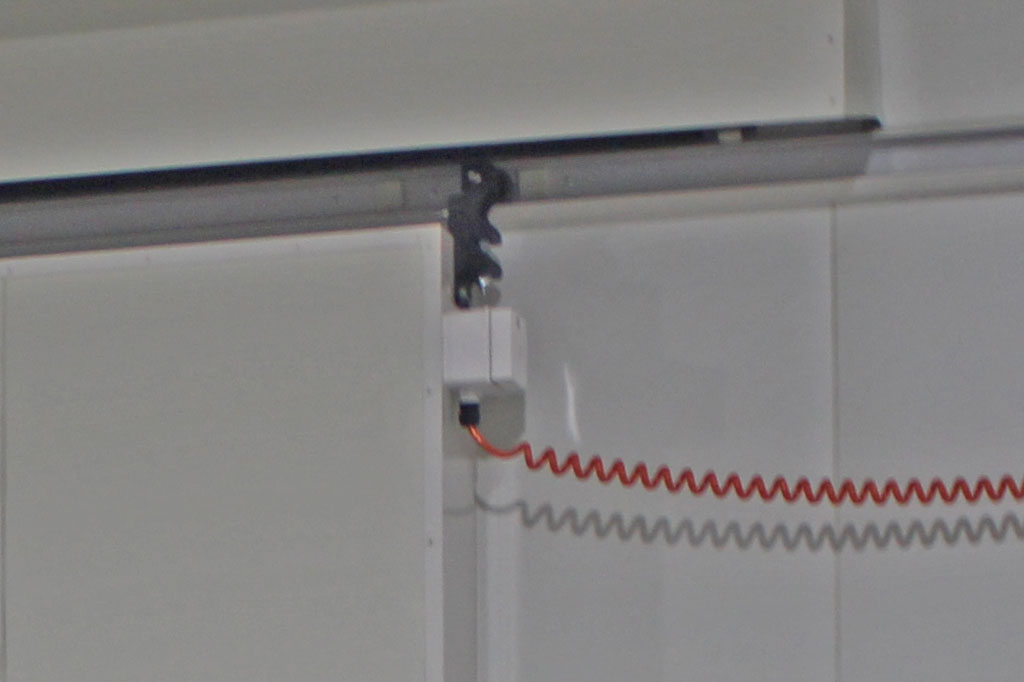

A. Standard with aluminum mill finish alloy extrusion and track.

B. Nylon wheels eliminate metal to metal contact.

C. Front and back floor guides with nylon inserts to eliminate metal to metal contact.

D. Front and back floor guides with nylon inserts to eliminate metal to metal contact. Available on all Sliding Doors.

E. Medium and low temperature drop down track.

A. Doors come with either loop handle (Process Sliding Door) or the S/S lever handle and wall bracket (Medium & Low Temperature Sliding Doors)

B. Wall locking bracket available with the Medium & Low Temperature Sliding Doors

C. Available with the internal flush dish handle (Process Sliding Door) or S/S internal flush dish handle (Medium & Low Temperature Sliding Doors)

A. Full surround frame

B. Powdercoated aluminum extrusions and track.

C. Door leaf from XFLAM, PIR fire rated insulated panel.

D. Full length track hood.

E. Full automatic operation.

F. Chequer plate.

G. S/S kickplates available on the Medium & Low Temperature Sliding Doors.

H. S/S kick plate.

I. Heated sill.